Predicting stuck pipe and preventing potential borehole collapse through automatic diagnostics

Predicting stuck pipe and preventing potential borehole collapse through automatic diagnostics

Overview

Operator: Vår Energi

Well Type: Exploration

Rig Type: Semi-submersible

Background

Vår Energi utilized wellAhead during an exploration well in the North Sea, with the eDrilling team advising on the software related diagnostics and observations.

A potential borehole collapse and a stuck pipe incident was prevented using eDrilling's automated monitoring software wellAhead, which provides real-time diagnostic support.

Automatic Diagnostics

The AI-based software detected the fluctuating real-time SPP values and their inconsistencies with the modeled SPP values, which pointed towards a potential pack-off situation. In addition, wellAhead triggered and automatic diagnostic during POOH, highlighting low ECD values potentially risking a borehole collapse and cuttings accumulation - a reinforcement of eDrilling's commitment towards enabling safer and greener energy operations.

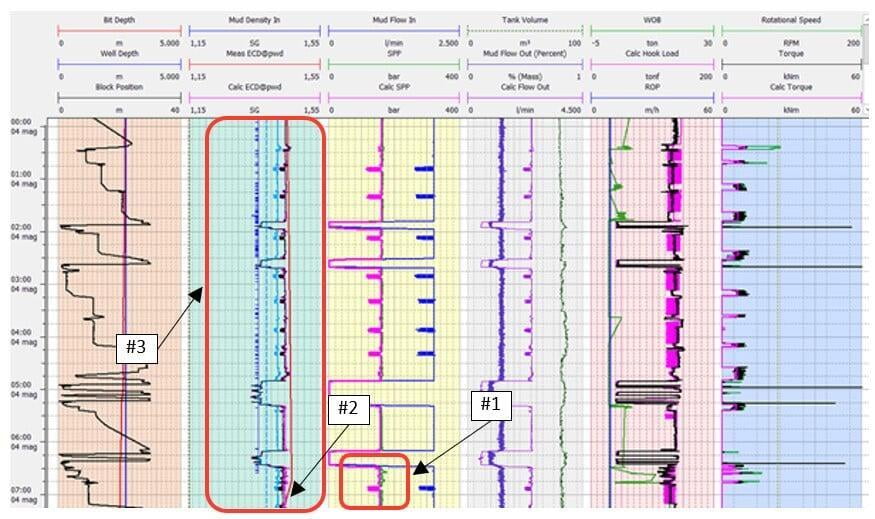

During pressure points acquisition with LWD in the 8 ½” open hole section, wellAhead showed an increasing and fluctuating real-time measured SPP compared to modelled SPP between 5 to 18 bar [#1], at approximately 06:30. This pointed towards a potential pack off situation. The software provided the following diagnostic messages below.

DATE/TIME: 04.05.2021/06:30

DEPTH [mMD]: 1854

WARNING/NOTIFICATION: Calculated ECD below collapse pressure

RISK: Early warning collapse

RECOMMENDATION: Increase flow rate to keep ECD above collapse pressure

Simultaneously, an automatic diagnostic was triggered during POOH without circulating, stating that the ECD was lower than collapse pressure [#2], risking borehole collapse. Earlier observations showed measured ECD higher than the modelled ECD [#3] before the reduction to below collapse pressure at approximately 07:00. This shows a potential collapsed borehole and/or cuttings accumulation, which was also highlighted by the eDrilling advisory team.

Result

Revision of the new information and observations resulted in a change of plans, reducing the number of pressure points acquisition, to avoid downhole risks and potential stuck pipe incident.